Multidirectional (3D) forging press

YHA3 Series Intelligent 3D Forging Hydraulic Press

Why Choose Us

Key Features

3D Multi-Directional Forging

Simultaneous X/Y/Z-axis pressure for complex geometries (blades, gears, etc.) in a single operation.

Dynamic pressure compensation ensures uniform forging depth (±0.05mm tolerance).

AI-Powered Control

Smart process library auto-adjusts parameters based on material deformation curves.

Real-time monitoring of pressure, temperature, and displacement with error alerts.

Energy-Efficient Performance

Servo-hydraulic system cuts energy use by 30% with rapid response (<0.1 sec).

Quick-change modular molds reduce setup time by 50%.

Applications

Aerospace: Turbine discs, engine blades.

Automotive: Axles, suspension components.

Energy: Nuclear flanges, valve bodies.

Service & Support

24/7 technical support | Free process design | Lifetime maintenance

Solving Industry Pain Points

Traditional Forging: Multiple reheating → material waste + oxidation.

Our Solution: Near-net-shape forming boosts material yield by 40%.

High Mold Costs: Complex parts require multiple dies.

Our Solution: Adaptive die system handles multi-profile parts with 1 mold set.

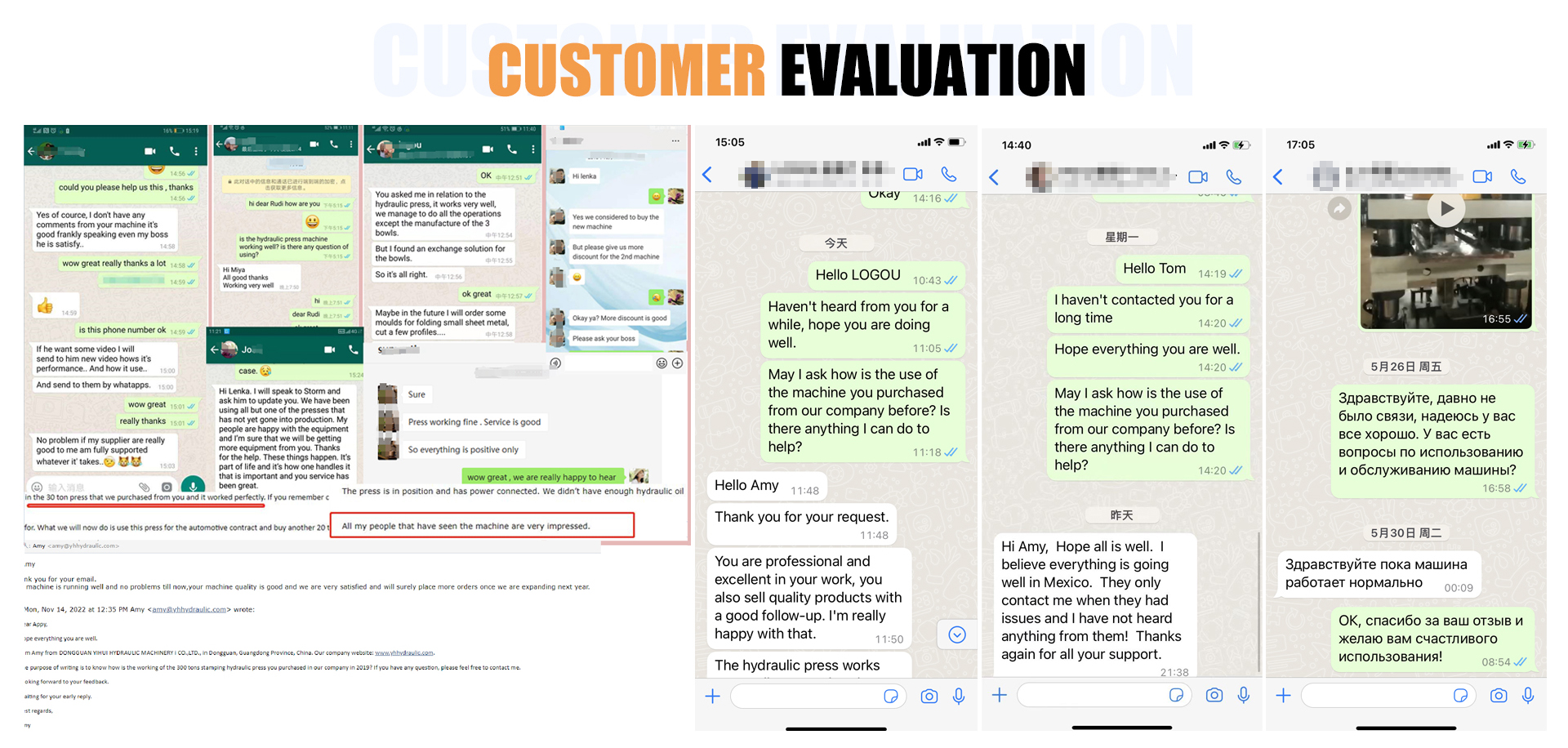

Trust Indicators

Patents: US/EP [Patent Numbers]

Clients: [Logos of Airbus/Toyota/Siemens etc.]

Certifications: ISO 9001, CE, ASME

YIHUI Hydraulic press with servo system,can bring you 10 kinds Advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% - 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

Products Description

1, Three-way multi-way forging press equipment adopts servo imported from Italy and Mitsubishi intelligent system control, intelligent operation is very high, strong stability.

2, the body of the solid steel plate after welding tempering treatment, using all directions of graphite copper guide guide, high compression precision, stable operation,

3, good rigidity, strong lateral force resistance, the cylinder adopts the whole forging process, Japan NOK seals, wear resistance and high sealing

Scope of application:

Multi-direction forging press is suitable for stretching, bending, forming, blanking, flanging and other stamping processes, especially for the following fields:

1. Auto parts: body covering parts pressing, brake sheet forming, oil tank stretching, chassis pressing, axle housing bending, bumper;

2. Household appliances: press assembly of washing machine parts, rice cooker parts, TV parts, refrigerator parts, etc.

3. Kitchen utensils: sink, kettle utensils, stainless steel utensils, other kinds of containers

4. Forging and forging forming process of bicycle, sports equipment, medical instruments, aluminum products and other tubular and shaped parts

Product Paramenters

Sample Product

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and servo press, Such as cold forging press, hot forging press, powder compacting hydraulic press, heating hydraulic press, deep drawing hydraulic press, servo press and so on . The plant is established in 1999 ,covers an area of 8,000 square meters. We are strictly implement the ISO9001 , CE, and SGS,BV management standards.

YIHUI brand presses have been exported to over 80 countries, Across five continents, in Europe, there are Germany, Italy, France, Sweden, Spain, Portugal, the United Kingdom, and so on. In the Americas, there are the USA, Brazil, Chile, Argentina, and so on. In Asia, there are Japan, South Korea, Malaysia, Indonesia, Singapore, Thailand, Vietnam, etc. In Africa, there are South Africa, Algeria, etc. Hydraulic press machine and servo press mainly applied to hardware, automotive, powder compacting,die casting, electronic, auto parts and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.