Hot Forging Press

Product name: Hot forging hydraulic press

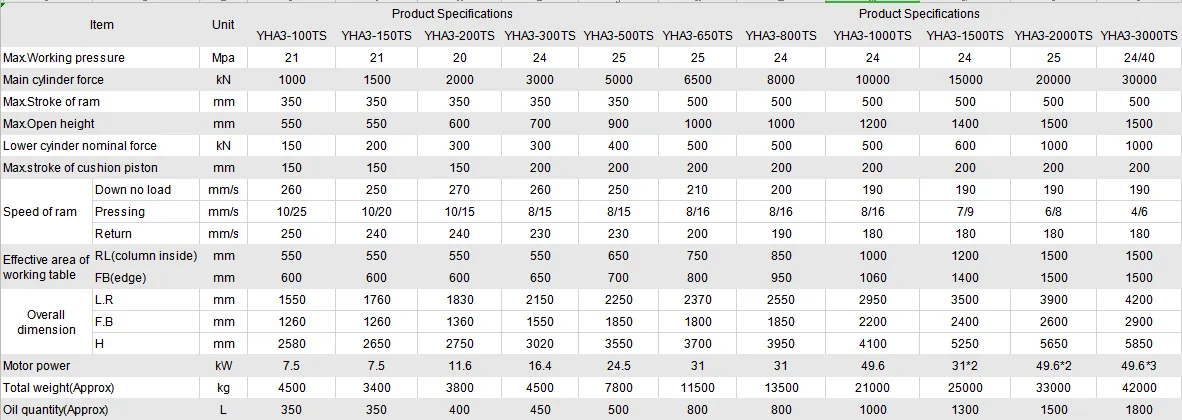

The main technical parameters:

Key Specifications

TECHNICAL PARAMETERS:

• Nominal Pressure: 500-5000T

• Table Size: 1200×1200mm

• Daylight Opening: 1250mm

• Ram Stroke: 800mm

• Approaching Speed: 80mm/s

• Return Speed: 120mm/s

• System Pressure: 31.5MPa

• Motor Power: 55kW

Why Choose Our Forging Press?

✓ Rexroth hydraulic system (German technology) for unmatched stability

✓ Patented hot forging technology reduces energy consumption by 30%

✓ Intelligent temperature control (±5℃ precision)

✓ Automatic lubrication system minimizes maintenance

✓ High-strength alloy frame with 15+ years service life

Applications

Ideal For:

- Automotive: Crankshafts, connecting rods, gear forging

- Aerospace: Titanium/alloy component forming

- Tool Manufacturing: Wrenches, pliers production

- Defense: Special metal parts fabrication

Technology Breakdown

Innovation Highlights:

- Multi-stage Pressure Control: Precise forging pressure adjustment

- Quick Die-change System: Reduces downtime by up to 40%

- Smart Diagnostics: Real-time condition monitoring

- Energy Recovery Unit: Cuts operational costs significantly

Case Study

"2000T forging press installed for BYD Auto Parts increased daily output by 40% while reducing energy use by 25%"

Service Commitment

✓ 24-month warranty

✓ 48-hour emergency response

✓ Free operator training

✓ Lifetime technical support

Hot Forging Press FAQ

1. Technology & Performance

Q: What types of hot forging presses do you manufacture? A: We offer a comprehensive range of equipment, including clutch-operated mechanical forging presses, servo-driven presses, and hydraulic hot forging presses. Our capacities range from 400 tons to over 5000 tons, catering to everything from small precision components to heavy-duty industrial forgings.

Q: How does the machine ensure forging precision? A: Precision is guaranteed through several key features:

High-Rigidity Frame: Robust steel-cast or welded structures minimize deflection under heavy loads.

Long-Guide Slides: High-precision X-type or 8-face guides ensure stable slide movement even under eccentric loading.

Thermal Compensation: Systems designed to manage material expansion caused by high-temperature environments, maintaining tight tolerances.

2. Applications & Materials

Q: What materials can be processed with these presses? A: Our machines are versatile and can handle carbon steel, alloy steel, stainless steel, aluminum alloys, copper, and titanium. The stroke and energy settings can be optimized based on the deformation resistance of the specific alloy.

Q: Which industries typically use your hot forging equipment? A: Our equipment is primarily utilized in:

-

Automotive: For crankshafts, connecting rods, gears, and steering knuckles.

-

Aerospace: For turbine blades and structural airframe components.

-

Construction & Agriculture: For track links, hydraulic valves, and heavy axles.

-

Energy: For large-scale valves, flanges, and piping components.

3. Customization & Automation

Q: Do you offer turnkey solutions including die design? A: Yes. We provide full "Turnkey" services, which include Finite Element Analysis (FEA) for process simulation, custom die design, manufacturing, and on-site commissioning. We can optimize your process for single-station or multi-station forging.

Q: Can the press be integrated into an automated production line? A: Absolutely. Our presses are "Industry 4.0 ready" and feature interfaces for:

-

Robotic Arm or Walking Beam integration for automatic loading/unloading.

-

Synchronization with Induction Heating Furnaces.

-

Integrated Automatic Die Lubrication (Graphite/Water) systems.

4. Maintenance & After-Sales Support

Q: How do you handle die wear in high-temperature environments? A: Our presses are designed with a short contact time feature, which reduces the heat transfer from the workpiece to the die, significantly extending die life. Additionally, our advanced cooling and lubrication systems ensure the dies stay within optimal operating temperatures.

Q: What is included in your after-sales service package? A: We provide global support including:

-

Remote Diagnostics: Real-time troubleshooting via IoT-enabled control systems.

-

On-site Installation: Expert engineers dispatched for setup and calibration.

-

Operator Training: Comprehensive safety and maintenance training for your staff.

-

Spare Parts Logistics: A dedicated inventory of critical components available for rapid global shipping.

Procurement & Lead Times

Q: What is the typical lead time for a new press? A: Standard models usually have a lead time of 3-4 months. For large-scale, highly customized forging lines, the timeframe typically ranges from 6-8 months depending on the complexity.

Q: Does your equipment comply with international safety standards? A: Yes, all our machines are built to meet CE, ISO9001, and ANSI/OSHA safety standards to ensure compliance with local regulations in North America, Europe, and Asia.

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and servo press, Such as cold forging press, hot forging press, powder compacting hydraulic press, heating hydraulic press, deep drawing hydraulic press, servo press and so on . The plant is established in 1999 ,covers an area of 8,000 square meters. We are strictly implement the ISO9001 , CE, and SGS,BV management standards.

YIHUI brand presses have been exported to over 80 countries, Across five continents, in Europe, there are Germany, Italy, France, Sweden, Spain, Portugal, the United Kingdom, and so on. In the Americas, there are the USA, Brazil, Chile, Argentina, and so on. In Asia, there are Japan, South Korea, Malaysia, Indonesia, Singapore, Thailand, Vietnam, etc. In Africa, there are South Africa, Algeria, etc. Hydraulic press machine and servo press mainly applied to hardware, automotive, powder compacting,die casting, electronic, auto parts and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.