2 Ton Servo Press Fitting Machine Electric Servo Automatic Press Mounting Machine Servo Motor Press

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% - 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

Product Description

Electric Servo Presses

1.Product OverviewYHC series servo presses adopt a high-precision servo drive system to achieve closedloop inteligent control of pressure, displacement and speed. ithascore advantages such as energy saving and high efficiency, precision and stabiity, and lexible production. lt is widely used in high-precision pressingneeds in industries such as automobile manufacturing, 3C electronics, new energy, and medical devices.2 Core application industries and products

Auto parts: bearing pressing, gear assembly, brake pad testing

3C electronics: mobile phone button assembly, PCB board pressing, connector plug-in test

New energy batteries: battery cell pole piece welding, battery shell packagingMedical equipment: syringe assembly, surgical instrument riveting

Metal stamping: precision metal parts forming, rivet crimping

3. Product core advantages

Broad-spectrum adaptation. supports pres-fiting requirements from micro electronic components (0.1N) to large metal parts (200T), covering 99% of

industrial scenarios.

Intelligent process library. pre-store 100+ process recipes, one-click switching of diferent product parameters, reducing debugging time.

Zero defect guarantee: realtime monitoring of force-displacement curve, automatic elimination of defective products, and yield rate 299.9%.

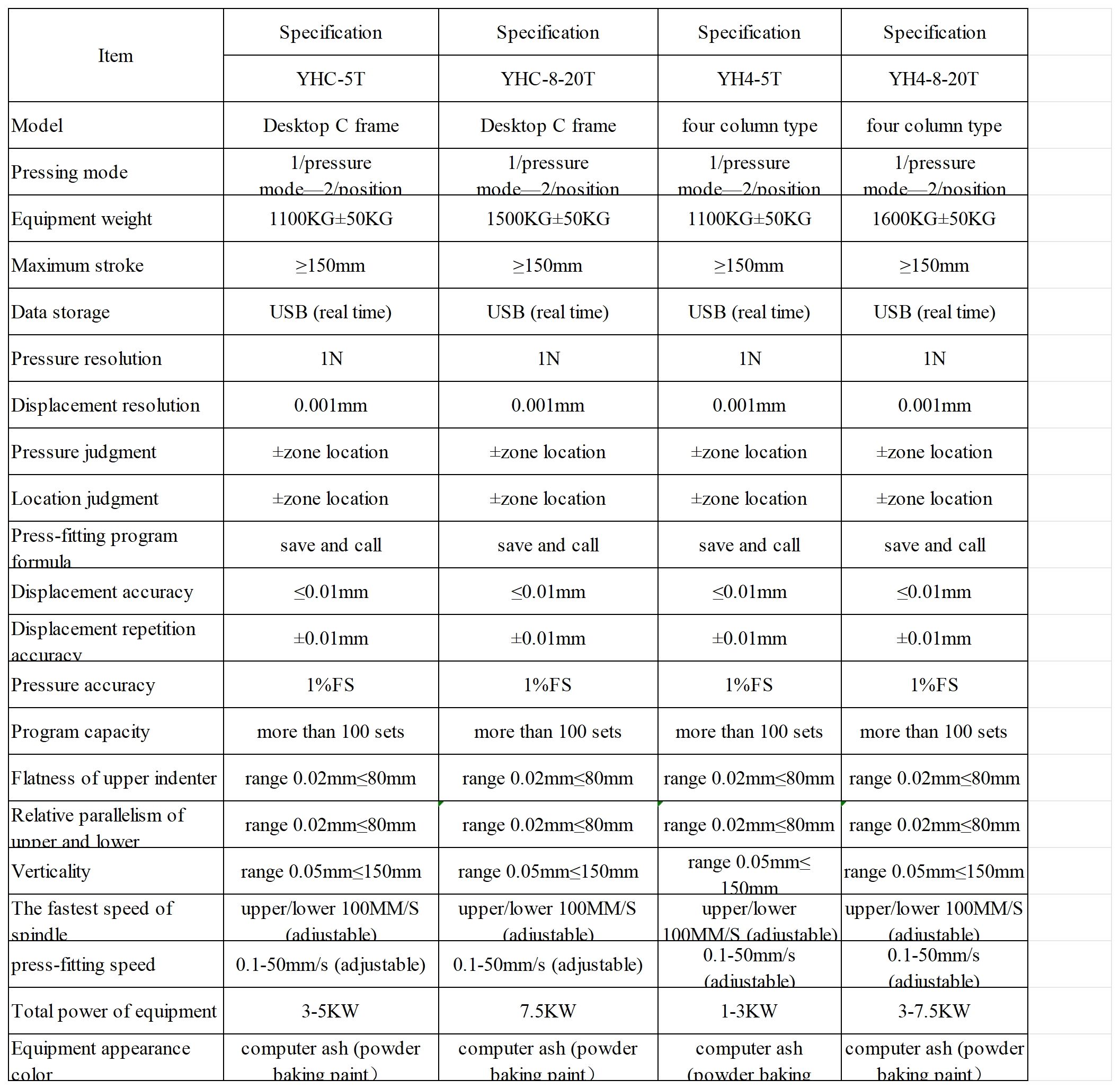

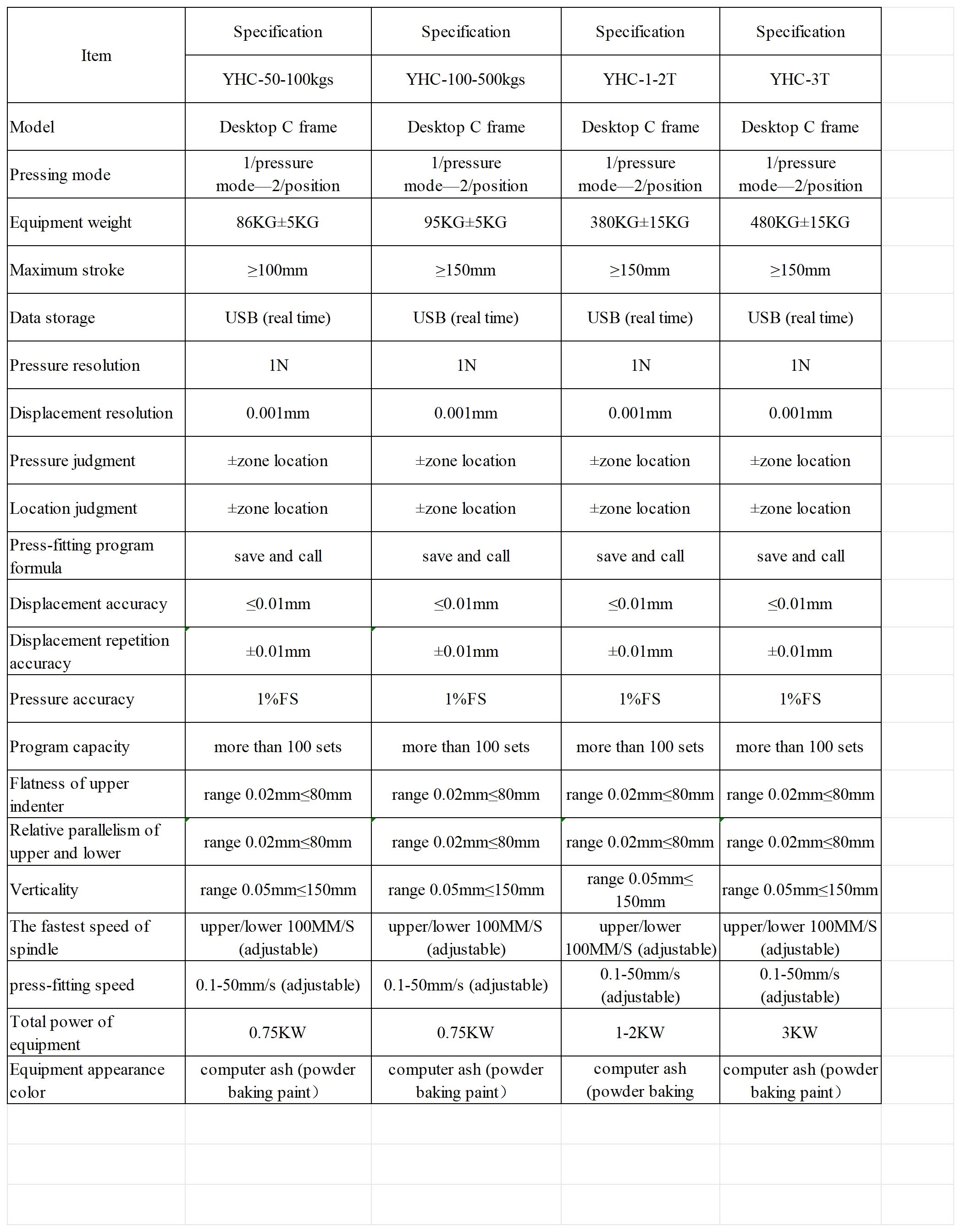

4.Technical parameters(example)

Pressure range:0.1~200T(customizable

Repeat positioning accuracy:+0.005mm

Energy saving efficiency: 50%~80% energy saving compared to hydraulic pressControl system:10.1-inch touch screen, supports data traceability

5.Customized service

Provide non-standard machine design, production ine intecration, and automation transformation services, We have customized special models such asultra-quiet press assembly and vacuum environment for customers such as XX Automobile and XX Electronic

sample products

parameter

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and servo press, Such as cold forging press, hot forging press, powder compacting hydraulic press, heating hydraulic press, deep drawing hydraulic press, servo press and so on . The plant is established in 1999 ,covers an area of 8,000 square meters. We are strictly implement the ISO9001 , CE, and SGS,BV management standards.

YIHUI brand presses have been exported to over 80 countries, Across five continents, in Europe, there are Germany, Italy, France, Sweden, Spain, Portugal, the United Kingdom, and so on. In the Americas, there are the USA, Brazil, Chile, Argentina, and so on. In Asia, there are Japan, South Korea, Malaysia, Indonesia, Singapore, Thailand, Vietnam, etc. In Africa, there are South Africa, Algeria, etc. Hydraulic press machine and servo press mainly applied to hardware, automotive, powder compacting,die casting, electronic, auto parts and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.