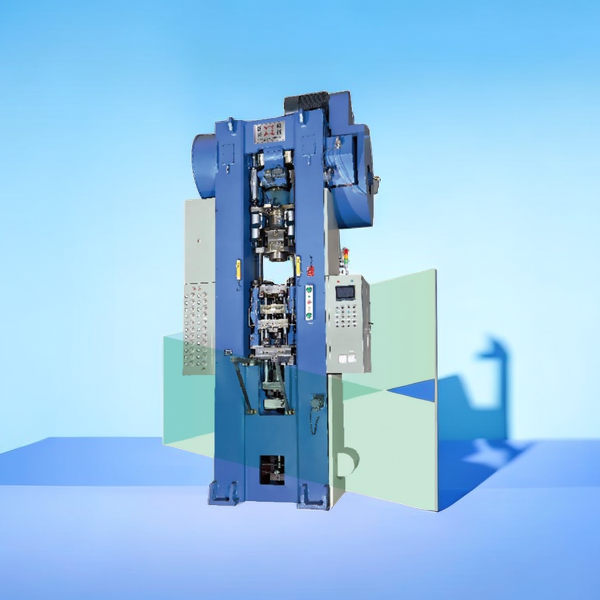

Fully automatic mechanical powder compacting press

Mechanical powder machine

Product Specifications

| Parameter name | 单位 | 规格 |

| Maximum pressing force | KN | 300 |

| Maximum modulus of force | KN | 180 |

| Maximum loading height | MM | 90 |

| Max out die stroke | MM | 60 |

| Upper slider stroke | MM | 125 |

| Upper slider adjustment range | MM | 50 |

| Forming times | N | 8-25 |

| More; less fill stroke | MM | 3 |

| Main motor power | KW | 5.5 |

| Final compression stroke | MM | 0-20 |

| Female die suface adjustment | MM | ±5 |

| Power Supply | 380V、3相50HZ | |

| Compressed air consumption | L/min | 55 |

| Negative template under pressure | KN | 150 |

| Double uprush inner punching capadily | KN | 150 |

| Double red outside the red bear | KN | 300 |

| A lower tolerance | KN | 300 |

| Two lower affordability | KN | 150 |

| A lower amount of adjustment | MM | 0-60 |

| Two undershoot adjustment | MM | 0-60 |

| Mandrel bearing force | KN | 150 |

| Punch fixing seat capacity | KN | 300 |

| A lower block adjustment | MM | 0-20 |

| Two lower block adjustment amount | MM | 0-20 |

| Weight of whole machine | T | 3.2 |

| Parameter name | unit | GX60T | GX100T |

| Maximum pressing force | KN | 600 | 1000 |

| Maximum modulus of force | KN | 300 | 500 |

| Maximum loading height | MM | 110 | 115 |

| Max out die stroke | MM | 65 | 70 |

| Upper slider stroke | MM | 160 | 160 |

| Upper slider adjustment range | MM | 80 | 80 |

| Forming times | N | 6-18 | 6-18 |

| More; less fill stroke | MM | 5 | 5 |

| Main motor power | KW | 7.5 | 15 |

| Final compression stroke | MM | 0-25 | 0-25 |

| Female die suface adjustment | MM | 士5 | ±5 |

| Power Supply | 380V、3相50HZ | 380V、3相50HZ | |

| Compressed air consumption | L/min | 80 | 120 |

| Negative template under pressure | KN | 300 | 500 |

| Double uprush inner punching capadiy | KN | 300 | 500 |

| Double red outside the red bear | KN | 600 | 1000 |

| A lower tolerance | KN | 600 | 1000 |

| Two lower affordability | KN | 300 | 500 |

| A lower amount of adjustment | MM | 0-80 | 0-80 |

| Two undershoot adjustment | MM | 0-80 | 0-80 |

| Mandrel bearing force | KN | 150 | 180 |

| Punch fiuing seat capacity | KN | 600 | 1000 |

| A lower block adjustment | MM | 0-20 | 0-20 |

| Two lower block adjustment amount | MM | 0-20 | 0-20 |

| Weight of whole machine | T | 7.5 | 12 |

| Parameter name | unit |

160T |

200T |

260T |

320T |

400T |

500T |

| Maximum pressing force | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| Maximum modulus of force | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| Maximum loading height | MM | 150 | 150 | 150 | 150 | 150 | 150 |

| Max out die stroke | MM | 100 | 100 | 100 | 100 | 100 | 100 |

| Upper slider stroke | MM | 180 | 190 | 190 | 200 | 210 | 225 |

| Upper slider adjustment range | MM | 85 | 90 | 90 | 90 | 90 | 90 |

| Forming times | N | 6-18 | 5-15 | 5-15 | 5-15 | 5-15 | 5-15 |

| More; less fll stroke | MM | 8 | 8 | 8 | 8 | 8 | 8 |

| Main motor power | KW | 22 | 30 | 37 | 45 | 50 | 60 |

| Final compression stroke | MM | 0-40 | 0-40 | 0-40 | 0-40 | 0-40 | 0-40 |

| Female die suface adjustment | MM | ±8 | ±12 | ±12 | +12 | ±12 | ±12 |

| Power Supply | 380V、3相50HZ | ||||||

| Compressed air consumption | L/min | 130 | 150 | 180 | 250 | 300 | 360 |

| Negative template under pressure | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| Double uprush inner punching capadily | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| Double red outside the red bear | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| A lower tolerance | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| Two lower affordability | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| A lower amount of adjustment | MM | 0-100 | 0-85 | 0-85 | 0-110 | 0-110 | 0-110 |

| Two undershoot adjustment | MM | 0-100 | 0-85 | 0-85 | 0-110 | 0-110 | 0-110 |

| Mandrel bearing force | KN | 200 | 200 | 260 | 300 | 400 | 500 |

| Punch fixing seat capacity | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| A lower block adjustment | MM | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Two lower block adjustment amount | MM | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Weight of whole machine | T | 18 | 26 | 30 | 38 | 45 | 55 |

Features:

●Adopt advanced computer touch screen operation, implement human-computer dialogue, and realize automatic adjustment of various functions. All adjustments are centrally controlled by the computer, which can store and recall process data of more than 100 products. Easy to operate and reduce labor intensity.

● Using a new C-type mold base (two upper, three lower), the inner and outer sides of the double upper punches can be mechanically adjusted, and the comprehensive filling mechanism performs filling to a certain extent, which can make up for the molding defects of complex or special-shaped pressed parts. (Special upper, three and lower four mold bases may be required)

● The comprehensive filling mechanism and pressing pressure adjustment device can maintain complex shapes and ensure the pressing effect. It implements initial pressure (upper punch insertion) and two-way pressing, upper punch pressurization and female mold floating (the female mold, first punch, and second lower punch can all float), and finally pressurized and ejected. And the parts are produced by the robot and the powder is automatically loaded.

● The mold ejection position and mold loading position are fixed.

Production parts

Production parts

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and servo press, Such as cold forging press, hot forging press, powder compacting hydraulic press, heating hydraulic press, deep drawing hydraulic press, servo press and so on . The plant is established in 1999 ,covers an area of 8,000 square meters. We are strictly implement the ISO9001 , CE, and SGS,BV management standards.

YIHUI brand presses have been exported to over 80 countries, Across five continents, in Europe, there are Germany, Italy, France, Sweden, Spain, Portugal, the United Kingdom, and so on. In the Americas, there are the USA, Brazil, Chile, Argentina, and so on. In Asia, there are Japan, South Korea, Malaysia, Indonesia, Singapore, Thailand, Vietnam, etc. In Africa, there are South Africa, Algeria, etc. Hydraulic press machine and servo press mainly applied to hardware, automotive, powder compacting,die casting, electronic, auto parts and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.