Product name: Four Column Forging Hydraulic Press

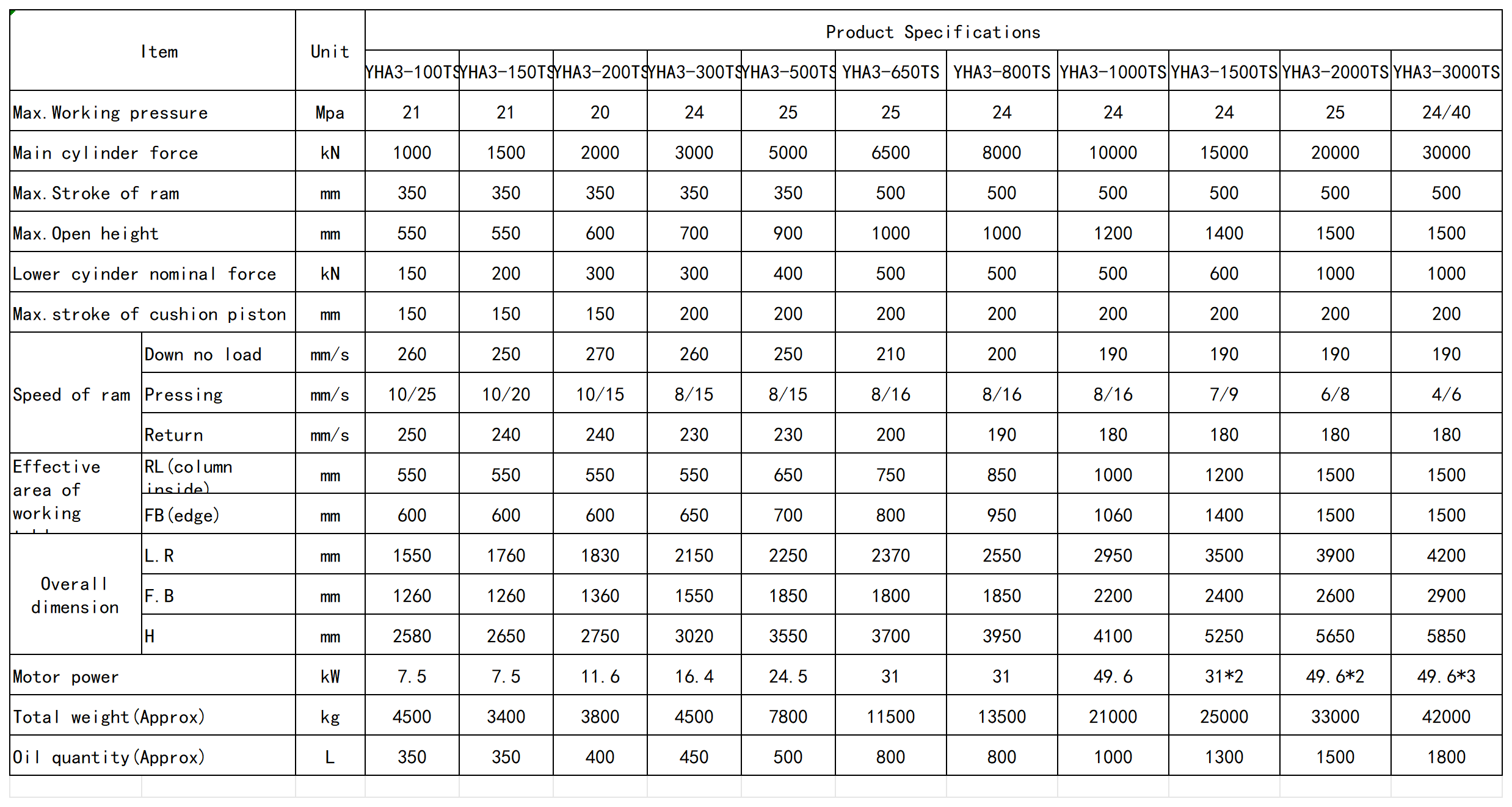

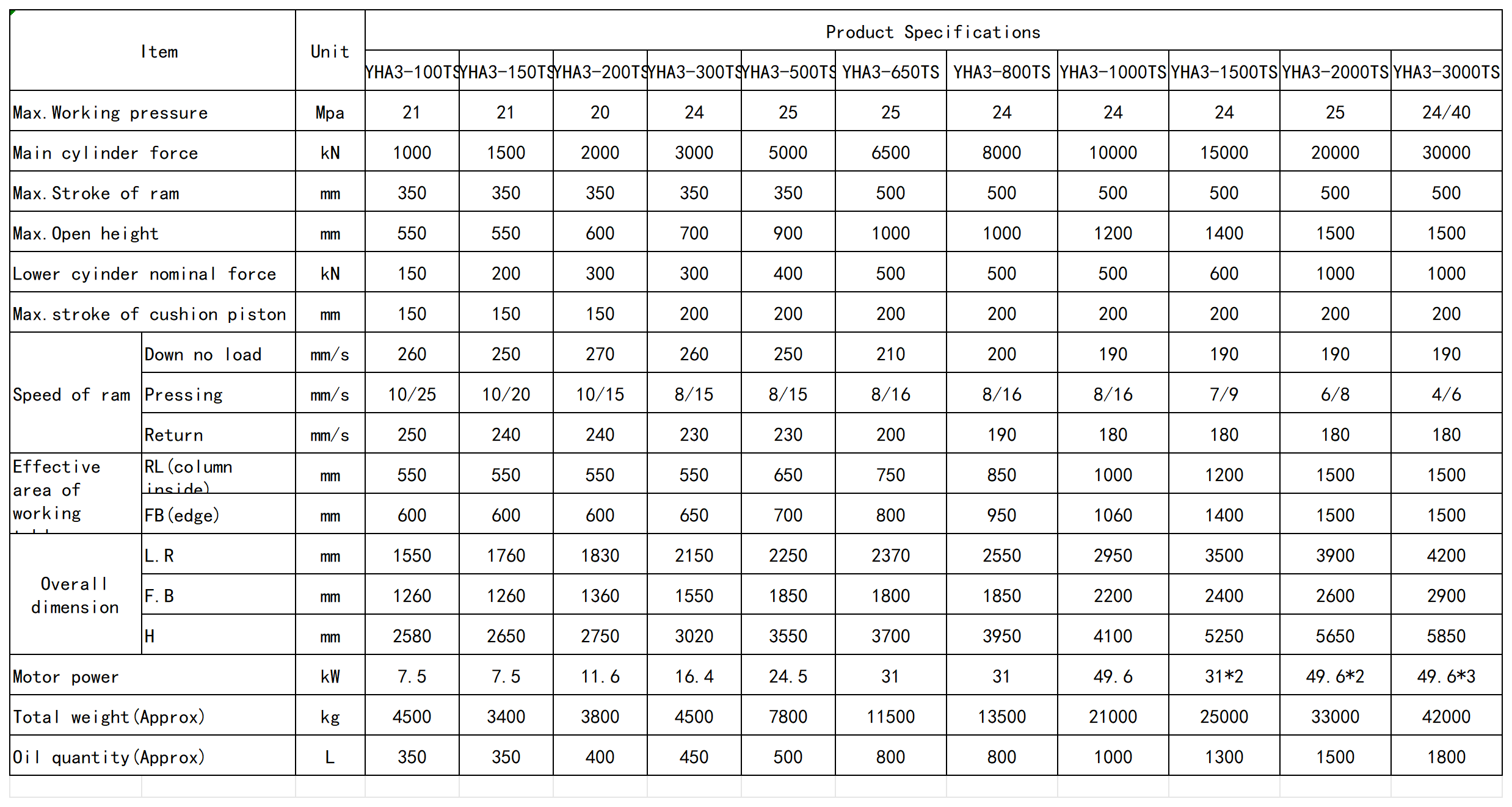

The main technical parameters:

The YHA3 Series Four-Column Hydraulic Press is engineered for high-performance metal forming, stamping, and forging applications. Built with premium steel and an advanced hydraulic system, it delivers exceptional stability, precision, and durability—ideal for automotive, appliance, hardware, and other industrial manufacturing.

Automotive Manufacturing

Key Features

1. Robust Structure

Four-column guided design ensures smooth operation & high precision

High-strength alloy steel columns, heat-treated & precision-ground

Welded steel frame for superior rigidity & anti-deflection performance

2. Advanced Hydraulic System

Premium hydraulic components (optional international brands)

Energy-saving circuit reduces power consumption by 30%

Oil temperature control for stable long-term operation

3. Intelligent Control

PLC + HMI touchscreen for easy operation

Programmable multi-stage pressure/speed control

Self-diagnostic function simplifies maintenance

4. Safety & Reliability

Dual-hand operation buttons

Photoelectric safety guards

Mechanical & hydraulic overload protection

Applications

Metal sheet forming

Automotive parts manufacturing

Appliance stamping

Hardware forging

Composite material pressing

Optional Configurations

Automatic feeding system

Mold heating system

Custom tonnage & table sizes

Data acquisition interface

Quality Assurance

Critical parts warranty (up to 10 years)

Rigorous factory testing before shipment

ISO & CE certified

Compliance with international safety standards

Service & Support

Free technical consultation

On-site installation & commissioning

Operator training

24/7 after-sales response

FAQ

What’s the lead time?

→ Standard models: 30-60 days; Custom orders

Does it require special foundation?

→ Yes, our engineers provide foundation drawings.

Maximum mold size?

→ Depends on model (e.g., YH-500T supports 900×900mm).

Energy consumption?

→ 30% lower than mechanical presses.

Maintenance interval?

→ Recommended every 500 operating hours.