Servo Press for Drone Motor Assembly

In the high-performance drone market, motor consistency is the key to flight stability. Our Precision Servo Press is engineered specifically for brushless motor (BLISS) manufacturing. By replacing traditional pneumatic or hydraulic methods, it offers programmable control over the entire press-fit process, ensuring zero damage to fragile magnets and micron-level bearing alignment.

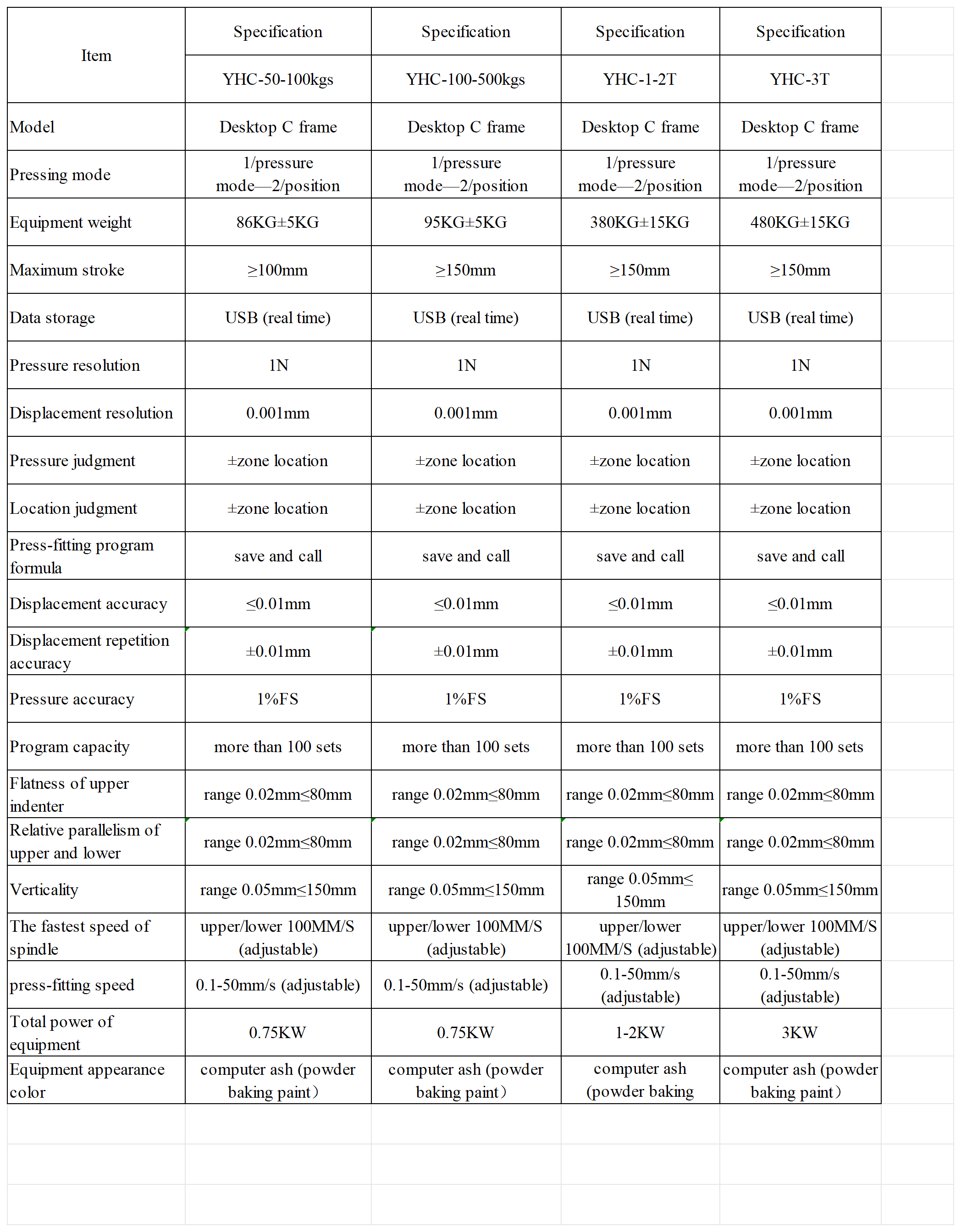

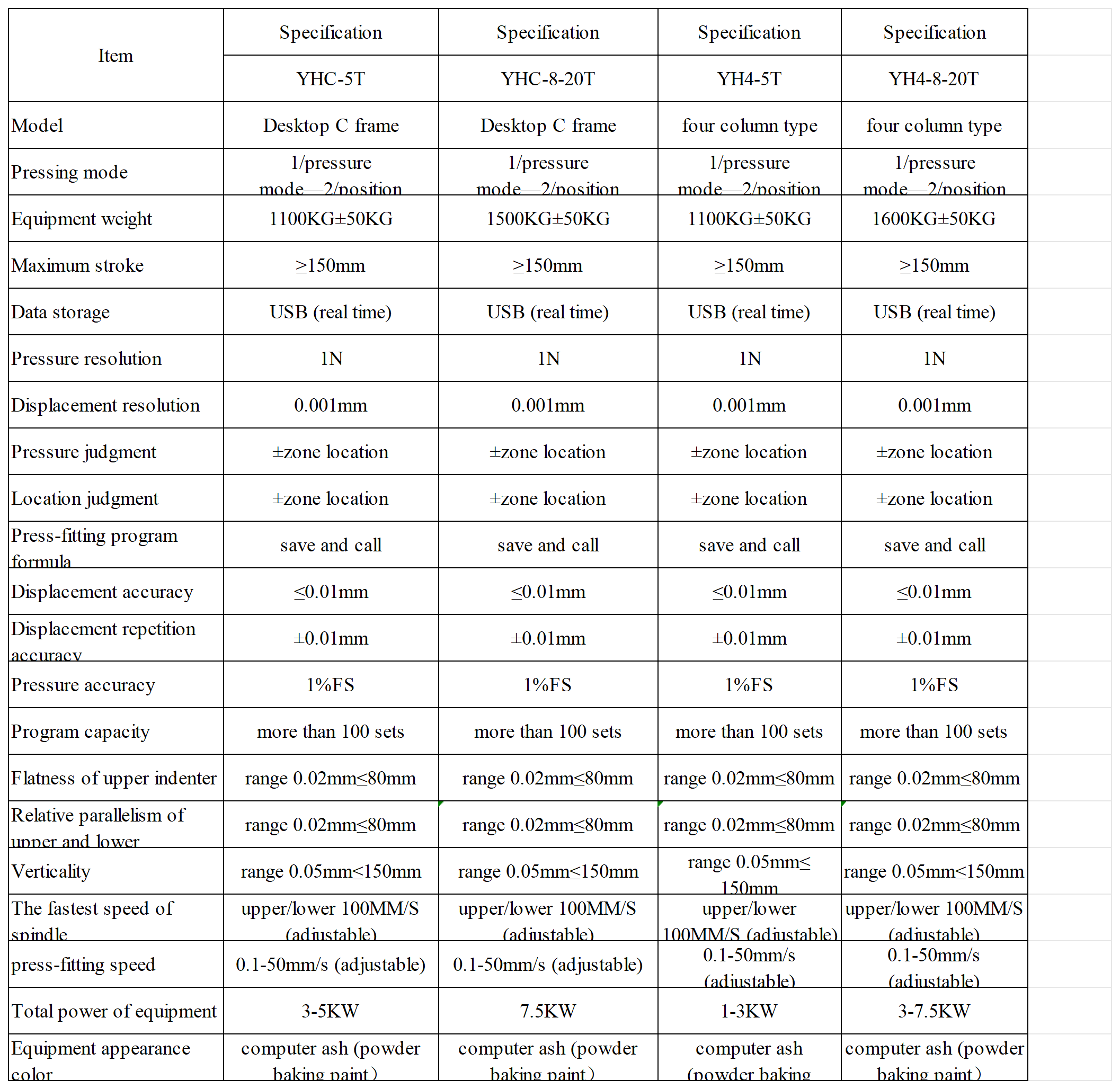

Technical Specifications

Key Features

Intelligent Quality Gate (Force-Displacement Analysis)

Our system captures the "digital signature" of every press cycle. If the pressure exceeds the limit at a specific displacement (indicating a burr or misalignment), the machine stops instantly and alerts the operator.

Benefit: Eliminates manual inspection and prevents defective motors from reaching the assembly line.

Protection of Sensitive Components

Drone motors use high-grade N52 neodymium magnets which are extremely brittle. The "Soft-Start" and "Constant Speed" modes of the servo motor ensure a smooth insertion, reducing scrap rates by up to 98%.

Full Traceability for Aerospace Standards

Every assembly's data (Force, Position, Time, Result) is automatically logged. You can export this data via USB or Ethernet to meet the strict quality tracking requirements of the aerospace industry.

Applications

Bearing Press-fit: Precision seating of high-speed ball bearings.

Shaft Insertion: Controlled insertion of motor shafts into the rotor.

Stator-Rotor Assembly: Managing the high magnetic pull during assembly.

Magnet Bonding & Pressing: Ensuring uniform pressure for adhesive curing or mechanical fits.

FAQ

Q: Can this machine handle multiple motor models?

A: Yes, you can store up to 100+ recipes (programs). Switching between models takes only seconds on the touch screen.

Q: Does it support MES (Manufacturing Execution System) integration?

A: Absolutely. Our servo press supports Profinet, EtherCAT, and Modbus for seamless factory automation.

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and servo press, Such as cold forging press, hot forging press, powder compacting hydraulic press, heating hydraulic press, deep drawing hydraulic press, servo press and so on . The plant is established in 1999 ,covers an area of 8,000 square meters. We are strictly implement the ISO9001 , CE, and SGS,BV management standards.

YIHUI brand presses have been exported to over 80 countries, Across five continents, in Europe, there are Germany, Italy, France, Sweden, Spain, Portugal, the United Kingdom, and so on. In the Americas, there are the USA, Brazil, Chile, Argentina, and so on. In Asia, there are Japan, South Korea, Malaysia, Indonesia, Singapore, Thailand, Vietnam, etc. In Africa, there are South Africa, Algeria, etc. Hydraulic press machine and servo press mainly applied to hardware, automotive, powder compacting,die casting, electronic, auto parts and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.